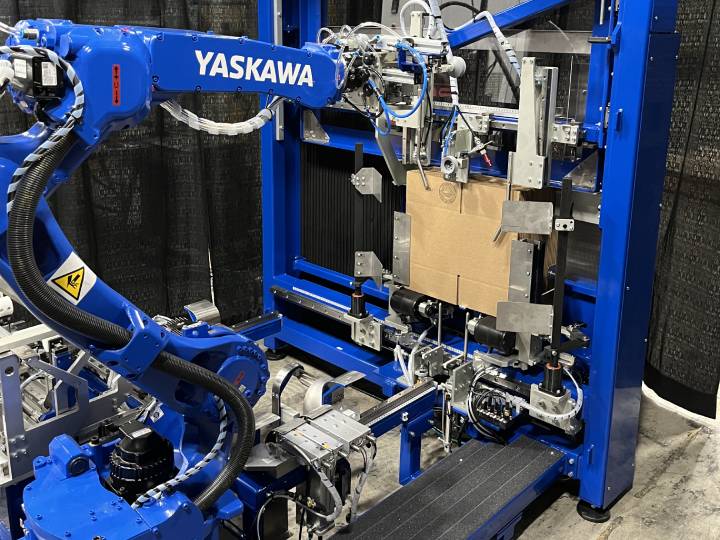

Custom Case & Tray packing equipment takes on many sizes & form factors and offer a creative alternative to conventional OEM equipment. A combination of tight footprint, high throughput or changeover requirements typically demands customized automation to achieve those goals. ProVantage uses a combination of custom gantries or integrated robots to solve problems in all aspects of case packing. Six axis robots for tight footprint case erection, delta robots for high speed packing & multi-axis servo changeover tooling are all core proficiencies with our automation team.

SOLUTIONS

Fully customizable solutions that meet a wide range of part sizes & case configurations. Delta and Six axis robots are used for small footprint case & tray erecting cells. End of arm tools are custom designed with either mechanical grippers or vacuum tooling, selected based on part features. Robotics can provide full solution from case erection to palletizing. All options available with auto tool change.

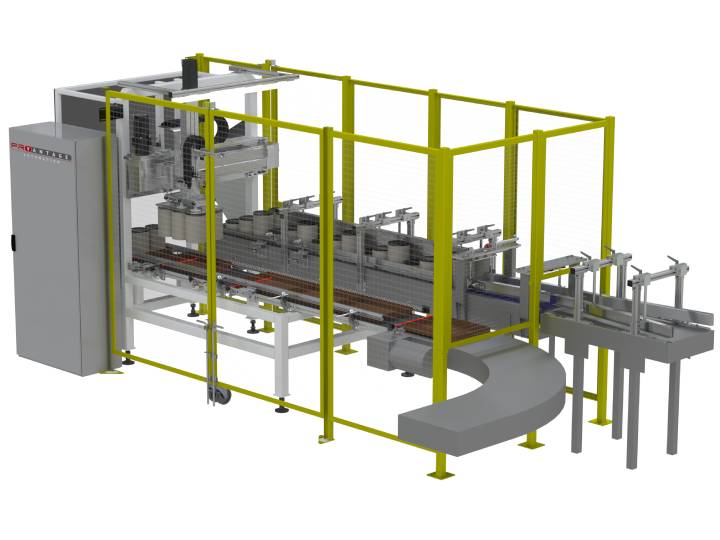

Either servo driven or robotic top loading options for case erectors combined with case handling equipment can provide intutive solutions with a more traditional linear footprint. Changeout tooling or servo adjustable grippers provide multiple options for part changeover to minimize downtime between product runs.

Servo controlled solution designed for large range capable of 6" to 24" case size with speeds of over 23 CPM. KDF formats include both RSC (regular slotted case) and HSC (Half slotted case) All options available with servo change over.

Common upgrades include conversions from pneumatic to servo to increase overall machine speed and reduce maintenace costs. Options vary from sectionalized upgrades to complete machine modernization.